About Us

For 75 years Fletcher Moorland has been providing engineering services to industry, when it comes to finding a company with the breadth of experience and range of services offered, you’ll be hard pushed to find one that matches Fletcher Moorland.

Life-cycle extension and maintenance is at the core of what we do, our workshops are open and operated 24 hours a day, 365 days a year because we know breakdowns and the need for reactive maintenance can be at any time.

Electric Motor

Repair

A very simple philosophy runs throughout our electric motor repair workshop, that all repairs and rewinds are to be as good as, if not better than new.

It’s not just something we say. We can prove it. Head to our website to take a look at our electric motor repair specification. Not all rewind companies do the same thing or work to the same standards. Ours is there with the best in the trade. We can say that with confidence too. We’ve achieved the EASA Accreditation for assuring the efficiency and reliability of repaired electric motors.

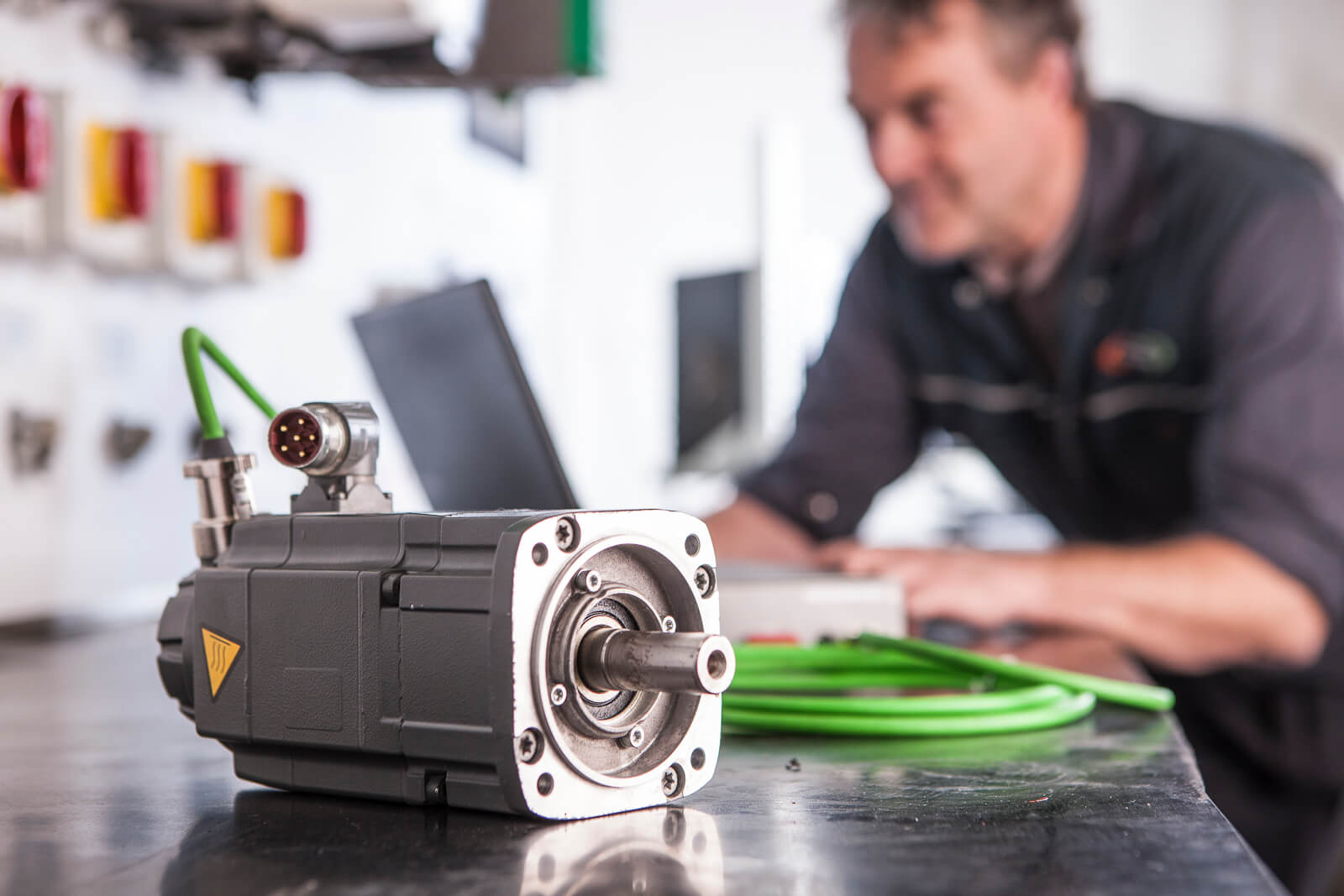

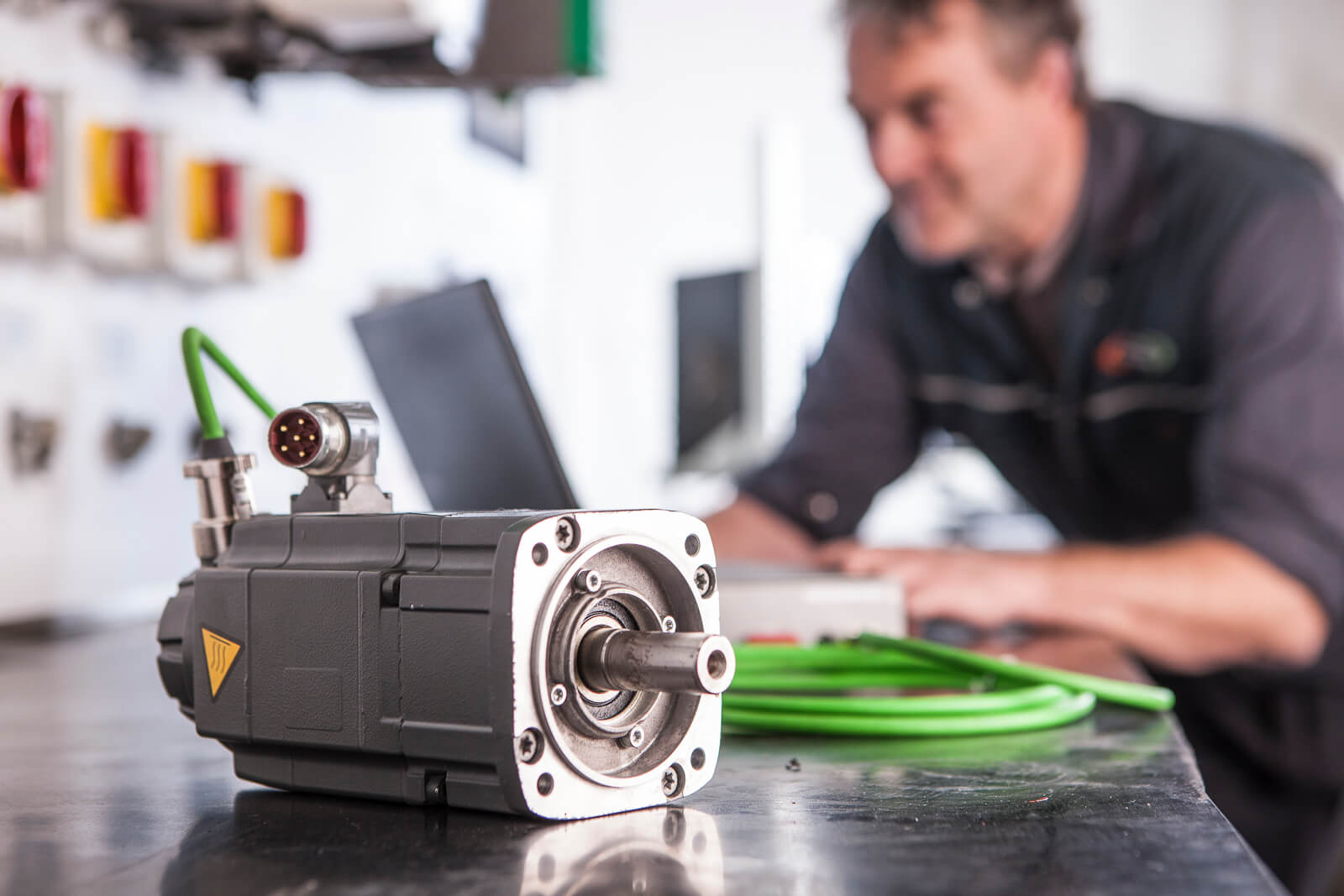

SERVO MOTOR

REPAIR

It was back in the early 1980s that we setup a servo motor repair department. they were much more simple back then than they are now however techniques to repair them were not widely understood.

We were the pioneers of servo motor repairs in the UK. It was interesting figuring out how they worked and designing test facilities for them. It’s our 35+ years’ experience in servo motor repairs that really does give us an authority in the trade.

We would not simply say ‘of course we can repair your servo motor!’

Keep it simple stupid - online condition monitoring'Keep It Simple Stupid'.The KISS philosophy is something that I think we should all do more of, my aging brain certainly thinks it's the best way to go for sure.It's an approach that I f...

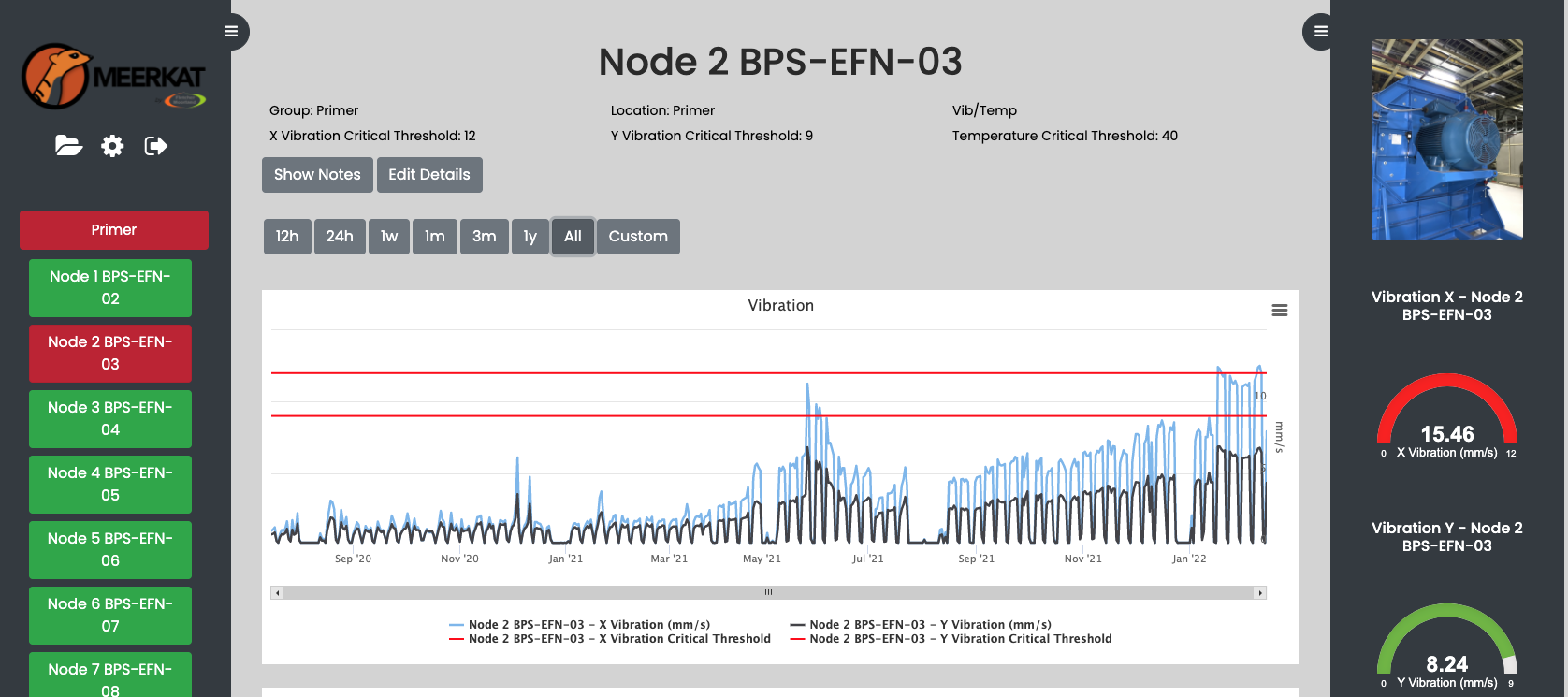

Meerkat condition monitoring system is five years old.

General, Meerkat NewsOur Meerkat condition monitoring system is five years old! (Feb 2022) It all began in early 2017 with a customer who had a critical piece of equipment in a location that was not too easily accessible. It was their main pump on a floating...

Meerkat saves a car plant €316,000 in six months!

Meerkat News, Newsautomotive plant confirmed HUge saving due to Meerkat!One UK automotive plant has confirmed a €316,000 saving in just six months by installing a Meerkat Remote Condition Monitoring System in their paint plant. This site specified a syste...

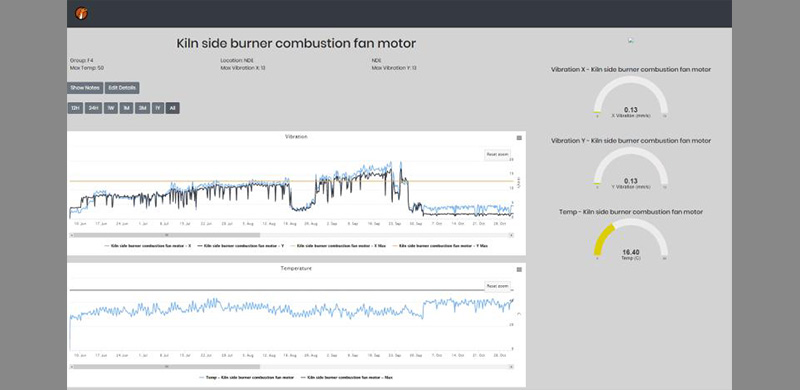

Benefits of online condition monitoring

Meerkat NewsMore and more people are seeing the benefit of having online condition monitoring systems installed on critical plant equipment. Josh is programming these base-stations for our largest installation of Meerkat so far. 405 vibration and te...

Increase productivity of your equipment

Meerkat NewsDo you want to increase productivity from your equipment? Then listen to what your plant is doing. Remote condition monitoring doesn’t just monitor the health of your equipment. It can give you crucial information as to things happening ...

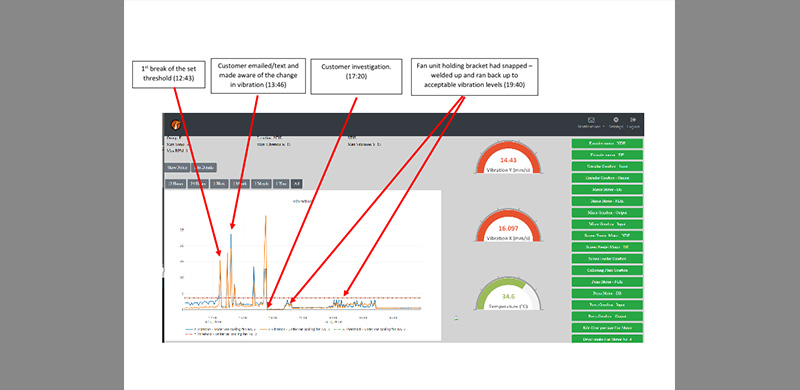

Early Warning of Failure

Meerkat NewsHere’s a brilliant example of where online condition monitoring has an advantage over route-based condition monitoring. It shows how quickly things can change and how quickly an online system can respond in providing an early warning of ...

Remote online condition Monitoring

Meerkat NewsThis is the sort of information that can literally save you thousands of pounds in lost production, downtime and spoilt product. It is real data taken from a remote online condition monitoring system that is installed on a brick making p...

On-line condition monitoring

Meerkat NewsThere certainly is a growing interest for on-line condition monitoring of plant. But it might not be right for you….. If you’re happy with a run-to-failure system and the downtime costs that come with it, this post won’t interest you. If...

HMI Repair

These days, it is hard to find modern day production machinery without hmis (human machine interfaces).

They certainly simplify the control and operation of machinery instead of having mechanical push buttons and illuminated switches; machine control is contained in one unit. They do suffer wear though; the good news is that most HMIs will let you know when they need a service. There are subtle things to look out for and if caught in time can save you an unexpected failure.

Repair &

Servicing

Fletcher Moorland is your one stop source for industrial equipment repair and servicing. We are open and manned 24 hours a day, every day of the week, that means weekends and bank holidays too, we are always open..

We are trusted and relied upon by the many UK and International companies to respond to their maintenance and breakdown needs by offering a quick and reliable repair & refurbishment on critical plant equipment.

High-quality

Repairs

Our approach is to provide the highest quality repair and refurbishment by working to best engineering practices and standards. We stand by our commitment that each repair and refurbishment is to be ‘as good as new’. Why not come and see for yourself how we make a difference for our customers? Come and audit our facility and compare against your current suppliers.

Contact us or call us on 01782 411021 anytime, day or night.

Latest News

Now that’s a pair of balls!

Electric Motor Repair, Linkedin, NewsOk, maybe not a typical opening to a website post but it's a good one. Here's an example of something that any user of electric motors doesn't want to see at all on their motor's bearings. The 'old favourite', signs of circulating shaft ...

Are you getting a true 24 hour pump service response?

Linkedin, News, Pump RepairPump Repair - service - supplyWhy wait when it's urgent? We know it's frustrating having to wait for a company to open when you've got a pump unit that needs an urgent repair. That's why we're open and manned 24/7 every day of the week. ...

Obsolete Rail Electronic Equipment Repair.

Automation Repair, Linkedin, NewsRefurbishment, servicing and repair of obsolete rail electronics.Because something is obsolete, it doesn’t mean that it can’t be supported. It doesn't meant that it can't be repaired. It doesn't mean that you have to upgrade it. This...

Autostore Robot AS-35085 servo motor refurbishment

News, Servo Motor RepairAutostore AS-35085 robot motor refurbishmentAutostore robot motors (part number AS-35085) are used on many of the Autostore robot units in distribution, sorter and pick systems worldwide. The motors are an Engel GNM8070/4 permanent magne...

Meerkat saves a car plant €316,000 in six months!

Meerkat News, Newsautomotive plant confirmed HUge saving due to Meerkat!One UK automotive plant has confirmed a €316,000 saving in just six months by installing a Meerkat Remote Condition Monitoring System in their paint plant. This site specified a syste...

A lot of work goes into an armature rewind

Electro Mechanical, General, News“I never knew how much work was involved!” That was a comment made by a visitor to our workshops earlier this week when we stopped by this DC electric motor armature being rewound. Many people make the assumption that the rewind is done ...

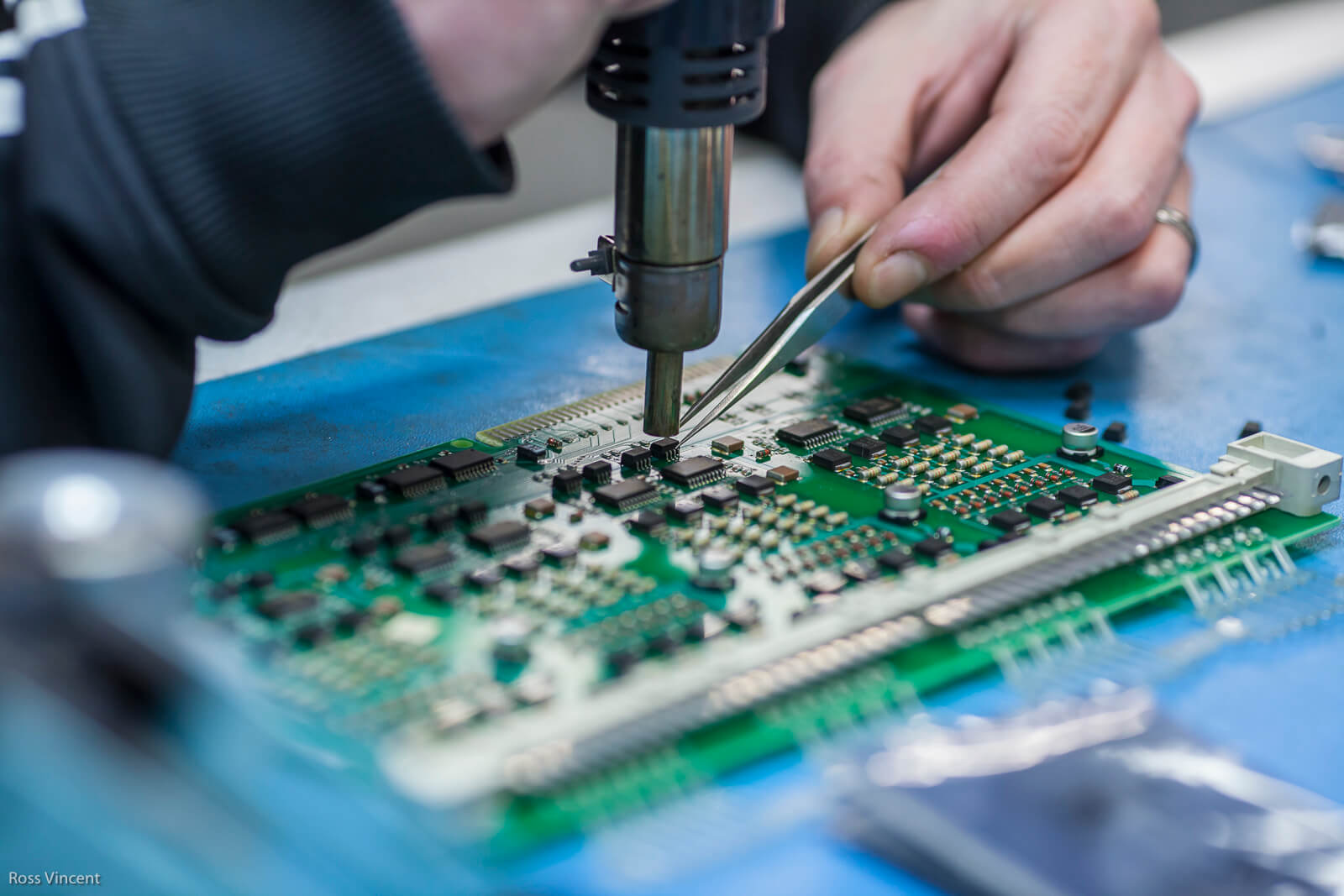

Don’t ditch that faulty PCB!

Automation Repair, General, NewsEstimates suggest that globally, around 60 million tonnes of waste electronic equipment are thrown away every year. As we fight the effects of global warming, growing pressure from consumers and environmental groups means this level of d...

Does rewinding reduce electric motor efficiency?

Electric Motor Repair, News, electric motor repair, RewindersThis 4 minute video explains why rewinding an electric motor does NOT reduce efficiency….providing it is done correctly with the correct processes, tools and follows the strict guidelines set out by EASA & AEMT....

Our Cores

Electro-Mechanical Repairs

Automation Control Repairs

Servo System Repairs

New

Challenge?

Looking for a change in career or a new challenge? We’re currently recruiting for various roles.

Take a look at our career opportunities.