Our Meerkat condition monitoring system is five years old! (Feb 2022)

It all began in early 2017 with a customer who had a critical piece of equipment in a location that was not too easily accessible. It was their main pump on a floating pontoon at a quarry. If the pump fails, the feed to the processing plant stops. They wanted a way to monitor it.

The first motor & pump that was fitted with Meerkat wireless vibration & temperature monitoring. (Feb 2017)

A wired system was out of the question so a wireless solution was needed. We found a suitable sensor with a wireless node and receiver. This was combined with a stand-alone HMI for signal processing. Whenever a predetermined level of vibration or temperature was breached, a signal light lit on the ‘shore-side’ equipment and in the maintenance office. The maintenance teams could then react to a problem.

The first local HMI control and alarm panel. (Feb 2017)

Pretty quickly, with iIoT and Industry4.0 being popular buzzwords, interest gathered. We knew that we needed to develop the system further and alter the alarm signalling system. A GSM gateway was installed to SMS message a mobile phone when an alarm was breached. This worked well as an entire maintenance team could be alerted to a problem happening. All along, we wanted the system to be a first-line alert of an early warning for teams to react and find out what was failing.

Meerkat standalone system demonstration kit. (2018)

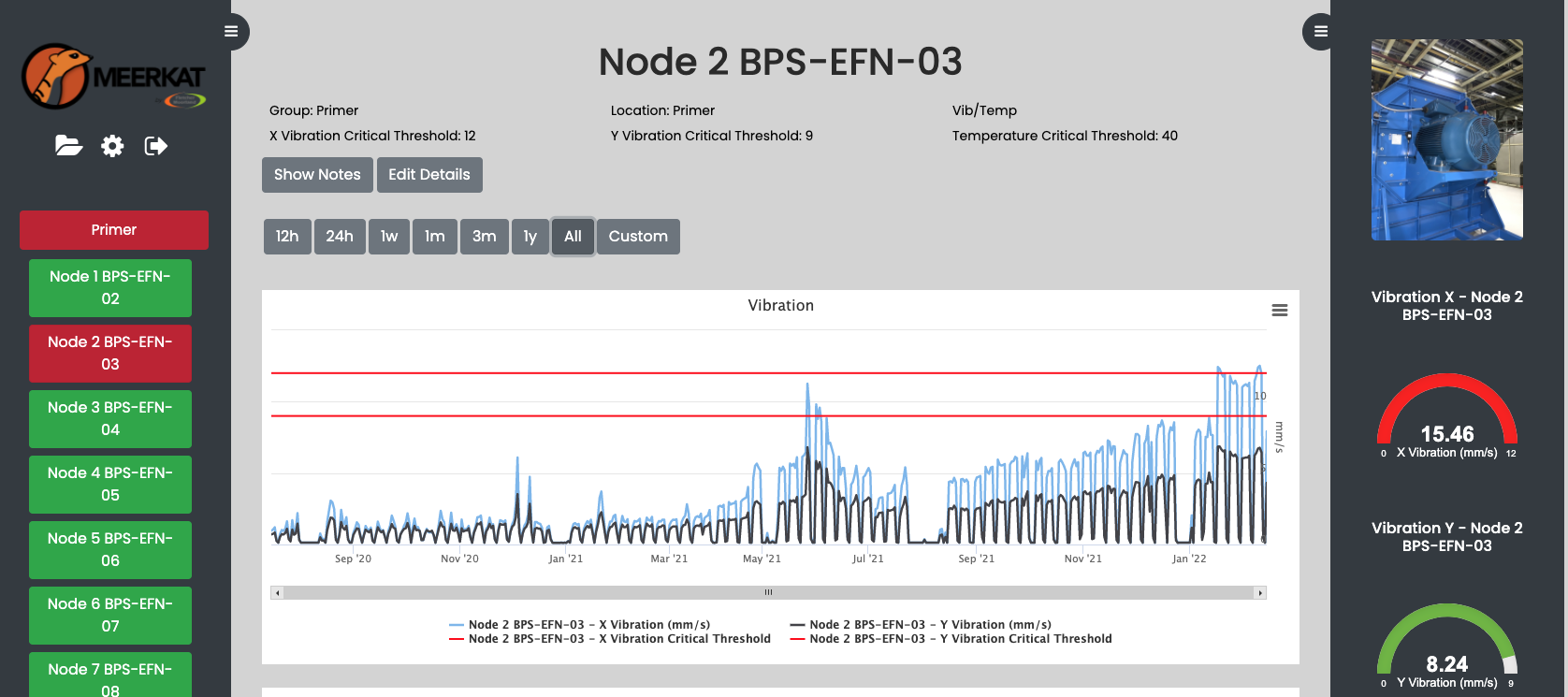

The next development improved the system and reduced hardware costs. That involved moving data from a standalone system to the cloud and a web-based dashboard. Anyone with the correct access could then view the data, trends could be seen, alarms and notes acknowledged.

Example of a live system at an automotive paint plant showing fan impellor imbalance. (2021)

So far, this is the version of Meerkat that’s been the most popular version in the market. Its low cost and ease of use has been its biggest selling point. There are close on 10,000 points in the UK and Ireland monitoring electric motors, pumps, fans and gearboxes. From a prestigious installation in London’s Scalpel building, Water pumping stations, Automotive plants, Brickworks, Steel mills, Food manufacturing, Retail distribution to our own workshop equipment. Meerkat is used in any industry.

Payback was within weeks for some customers with Meerkat preventing downtime.

Such was the success of the systems that requests to monitor more than vibration and temperature soon came our way. Sensors monitoring current, humidity, air fow, pressure, oil condition, fluid level and sound level have all been added to installed systems.

Fast forward to today and our R&D guys have been very busy indeed. Edge computing is now part of the Meerkat family. Monitoring systems can create a massive amount of data, edge computing can handle this more effectively and efficiently. Add a Raptor gateway to the system too, it becomes very powerful indeed with artificial intelligence and machine learning to identify potential issues starting to happen with equipment.

A combined wired and wireless Meerkat system with edge computing technology. (2022)

I’m not sure how to describe Meerkat these days. It’s more than condition monitoring, it’s Smart-Monitoring for almost anything.

#data

#ai

#machinelearning

#edgecomputing

#iiot

#conditionmonitoring

#productivity