Ok, maybe not a typical opening to a website post but it’s a good one. Here’s an example of something that any user of electric motors doesn’t want to see at all on their motor’s bearings. The ‘old favourite’, signs of circulating shaft current damage. The typical example that we’ve probably all seen in photos is the fluting or washboard …

Are you getting a true 24 hour pump service response?

Pump Repair – service – supplyWhy wait when it’s urgent? We know it’s frustrating having to wait for a company to open when you’ve got a pump unit that needs an urgent repair. That’s why we’re open and manned 24/7 every day of the week. There’s no need to wait until the morning or even until the weekend is over …

Obsolete Rail Electronic Equipment Repair.

Refurbishment, servicing and repair of obsolete rail electronics.Because something is obsolete, it doesn’t mean that it can’t be supported. It doesn’t meant that it can’t be repaired. It doesn’t mean that you have to upgrade it. This is especially true when it comes to electronic equipment used on the rail network. Take this sample of electronic items, these are some …

Autostore Robot AS-35085 servo motor refurbishment

Autostore AS-35085 robot motor refurbishmentAutostore robot motors (part number AS-35085) are used on many of the Autostore robot units in distribution, sorter and pick systems worldwide. The motors are an Engel GNM8070/4 permanent magnet DC servo motor. Our customers have found that these motors are either not readily available or on a long lead time so refurbishing these motors is …

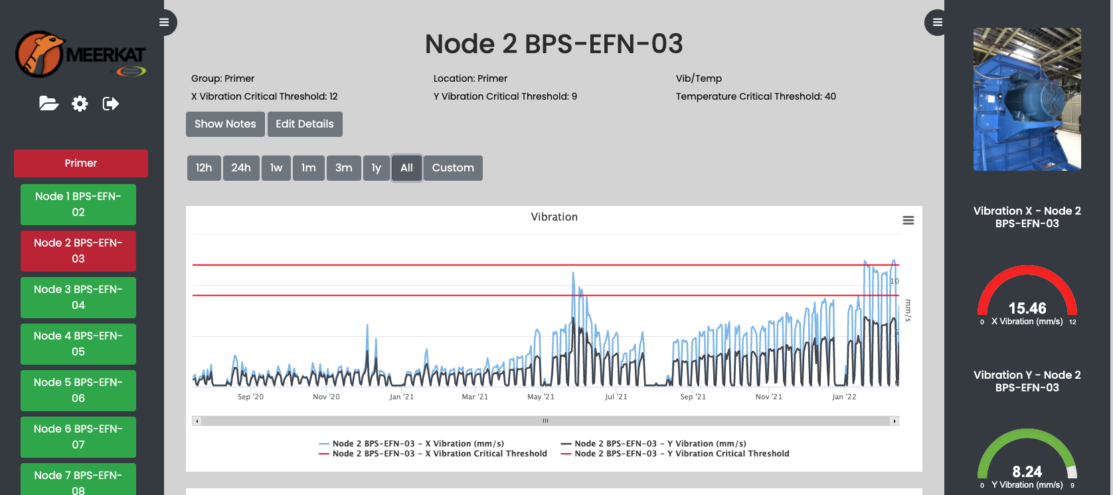

Meerkat saves a car plant €316,000 in six months!

automotive plant confirmed HUge saving due to Meerkat!One UK automotive plant has confirmed a €316,000 saving in just six months by installing a Meerkat Remote Condition Monitoring System in their paint plant. This site specified a system to monitor vibration, temperature and current on their paint plant air handing units. Typically a paint plants can suffer fan failures due to a number …

A lot of work goes into an armature rewind

“I never knew how much work was involved!” That was a comment made by a visitor to our workshops earlier this week when we stopped by this DC electric motor armature being rewound. Many people make the assumption that the rewind is done by machines. Whilst this is usually true when it’s made at the manufacturer’s factory, when it comes …

Don’t ditch that faulty PCB!

Estimates suggest that globally, around 60 million tonnes of waste electronic equipment are thrown away every year. As we fight the effects of global warming, growing pressure from consumers and environmental groups means this level of disposal is unacceptable. With this in mind, Matt Fletcher, Managing Director at Fletcher Moorland, dispels some myths surrounding the practice of repairing printed circuit …

Does rewinding reduce electric motor efficiency?

This 4 minute video explains why rewinding an electric motor does NOT reduce efficiency….providing it is done correctly with the correct processes, tools and follows the strict guidelines set out by EASA & AEMT. Here’s a link to the guidelines if you wish to read for yourself – Motor rewind efficiency study

“You can’t just switch it off and back on again, it’s not a computer!”

Whilst this may work when your PC or laptop stops working properly, it’s definitely not the thing to do when industrial automation equipment stops working. It might sound pretty obvious really but it is something that happens all too often. Just think about it for a moment, your machine tool or CNC stops working. There’s a reason for it, some …

“White gloves in a repair workshop. I bet they don’t stay white for long!”

Three times this was picked up on recently and all from visitors to our workshops. I have no idea what people expect when they visit a workshop, I should say that these people were buyers and not engineers. Maybe engineering still holds onto it’s wrongly-perceived image of ‘being dirty’ but engineering isn’t always about dirty shitty environments. Ok, sometimes we …