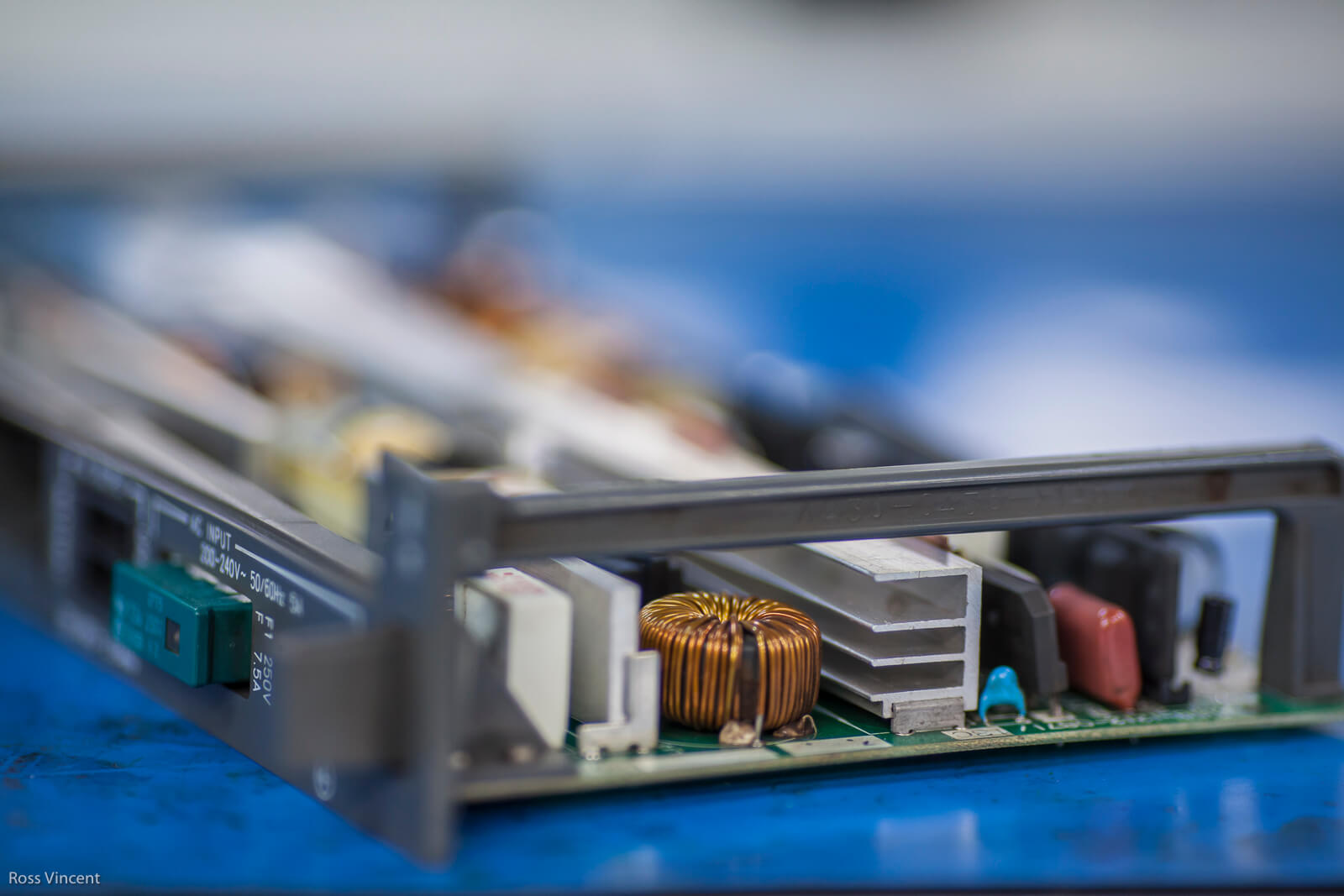

Power Supply

Repair

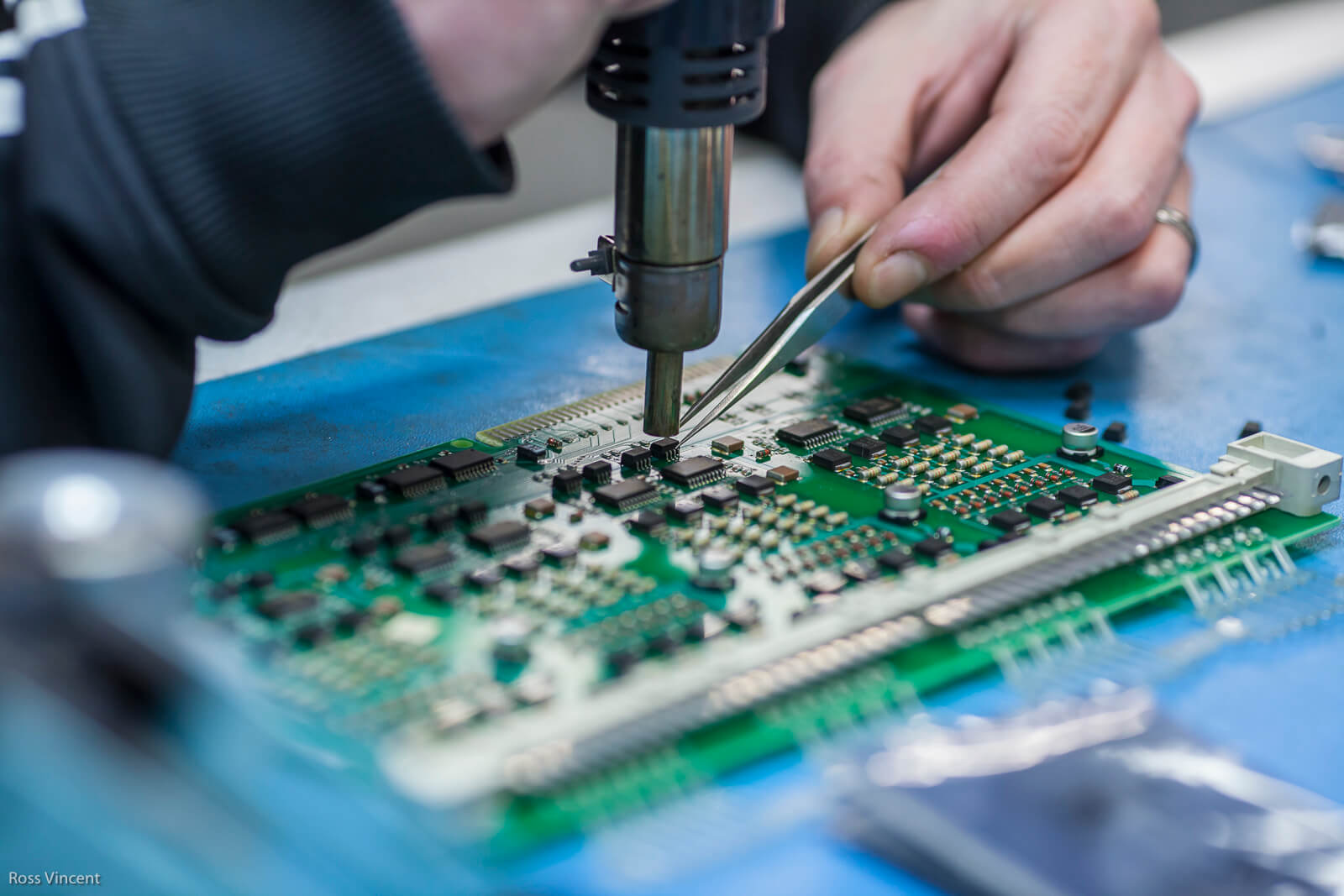

It’s not surprising that power supplies (psus) are one of the most common items of electronic automation equipment we see for repair.

After all, they work hard keeping control systems powered up. It’s often components that wear out and come to the end of their operating life that causes a PSU to fail. In our experience it’s not uncommon to see PSUs that are only 2-3 years old for repair. These are usually ones that are built to a cost rather than to a high specification.

Repairing

PSUs

Very often PSUs are made obsolete by the manufacturer in a relatively short period of time, that’s not usually a problem for us. We repair and service PSUs for certain rail customers of ours who have PSUs that were built in the 1960s. Whether it’s a single output PSU, a programmable logic controller PSU, a servo drive PSU or a multi output water cooled PSU, our workshops can fully refurbish all types.

Any PSU repaired or serviced by us goes through a full refurbishment, we don’t just repair the fault. All components that are near end-of-life are replaced and often upgraded. In a PSU these are mainly the electrolytic capacitors, they wear out and become resistive. All these capacitors are upgraded with 105˚C low ESR types as opposed to the 85˚C types most manufacturers fit as standard. In our experience doing this gives a greater life to the PSU when it’s returned to you.

Key services

- Full refurbishment and upgrade of wearing parts

- Replacement of capacitors, opto-isolators, relays, cooling fans, analogue switches

- Testing carried out on programmable dynamic loads

- Thermal image capture of PSU on test

- Static load test up to 100kW

- SERVICEview video of testing

- 12 month standard warranty

Power Supply News

Keep it simple stupid - online condition monitoring'Keep It Simple Stupid'.The KISS philosophy is something that I think we should all do more of, my aging brain certainly thinks it's the best way to go for sure.It's an approach that I f...

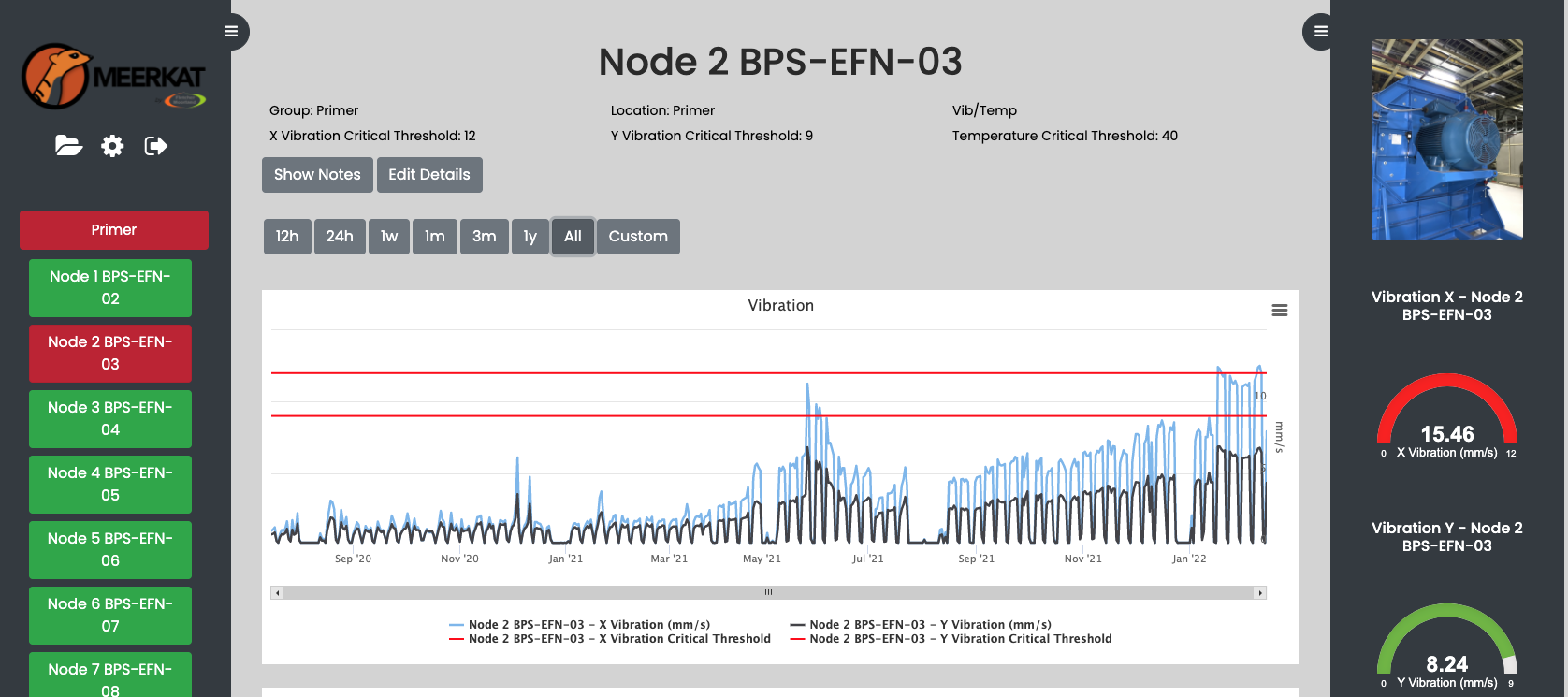

Meerkat condition monitoring system is five years old.

General, Meerkat NewsOur Meerkat condition monitoring system is five years old! (Feb 2022) It all began in early 2017 with a customer who had a critical piece of equipment in a location that was not too easily accessible. It was their main pump on a floating...

Meerkat saves a car plant €316,000 in six months!

Meerkat News, Newsautomotive plant confirmed HUge saving due to Meerkat!One UK automotive plant has confirmed a €316,000 saving in just six months by installing a Meerkat Remote Condition Monitoring System in their paint plant. This site specified a syste...

Benefits of online condition monitoring

Meerkat NewsMore and more people are seeing the benefit of having online condition monitoring systems installed on critical plant equipment. Josh is programming these base-stations for our largest installation of Meerkat so far. 405 vibration and te...

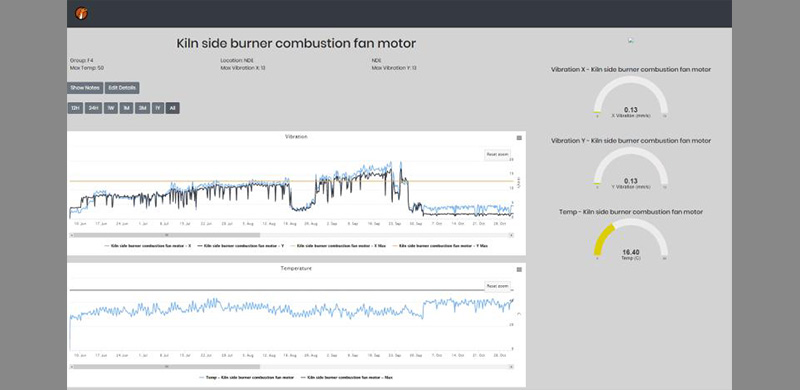

Increase productivity of your equipment

Meerkat NewsDo you want to increase productivity from your equipment? Then listen to what your plant is doing. Remote condition monitoring doesn’t just monitor the health of your equipment. It can give you crucial information as to things happening ...

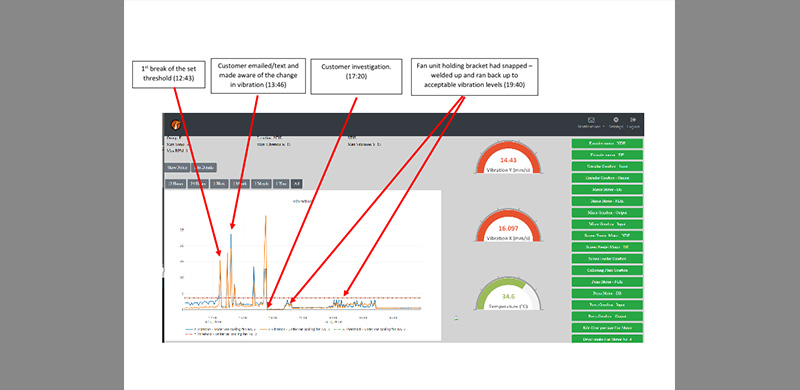

Early Warning of Failure

Meerkat NewsHere’s a brilliant example of where online condition monitoring has an advantage over route-based condition monitoring. It shows how quickly things can change and how quickly an online system can respond in providing an early warning of ...

Remote online condition Monitoring

Meerkat NewsThis is the sort of information that can literally save you thousands of pounds in lost production, downtime and spoilt product. It is real data taken from a remote online condition monitoring system that is installed on a brick making p...

On-line condition monitoring

Meerkat NewsThere certainly is a growing interest for on-line condition monitoring of plant. But it might not be right for you….. If you’re happy with a run-to-failure system and the downtime costs that come with it, this post won’t interest you. If...