This is the sort of information that can literally save you thousands of pounds in lost production, downtime and spoilt product.

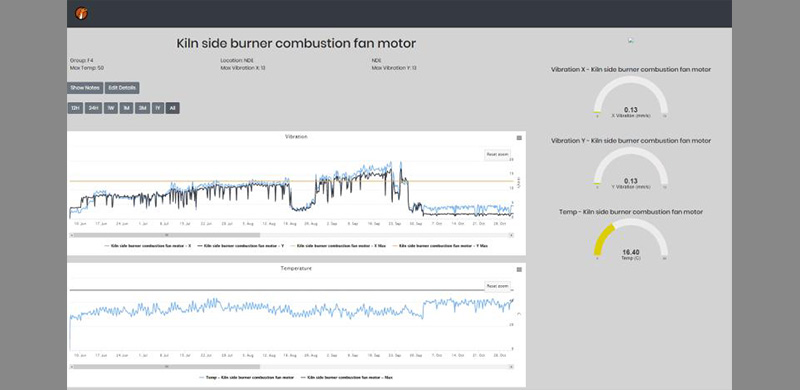

It is real data taken from a remote online condition monitoring system that is installed on a brick making plant.

It’s not really the data that’s important. It’s what you can do with it where there’s real value.

It gave an early warning of a motor bearing failure. It gave a maintenance team plenty of time to react. It prevented costly downtime.

That’s what we believe online monitoring should give you. An early warning of conditions changing so you can find out what the problem is, then schedule maintenance. ‘Before the machine schedules it for you.’

This graph shows vibration from the drive end of a 280kW fan motor. The vibration trend is increasing. The online system alerts when a threshold has been breached. This gave critical time for the site’s maintenance guys to confirm it was a bearing problem and to schedule in a replacement. The trace afterwards shows the vibration data after a spare motor had been fitted.

Pretty simple really, we like simplicity. So did our customer, that’s why they installed this system. It paid for itself by giving this one alert.